PRODUCTION TECHNIQUES

The action sequence for transforming raw material into ultra-slim leaves measuring a few microns, begins with the Fusion phase. This operation allows the metal to be brought to a liquid state, eliminating all its impurities, so as to make it solidify into the characteristic ingot shape.

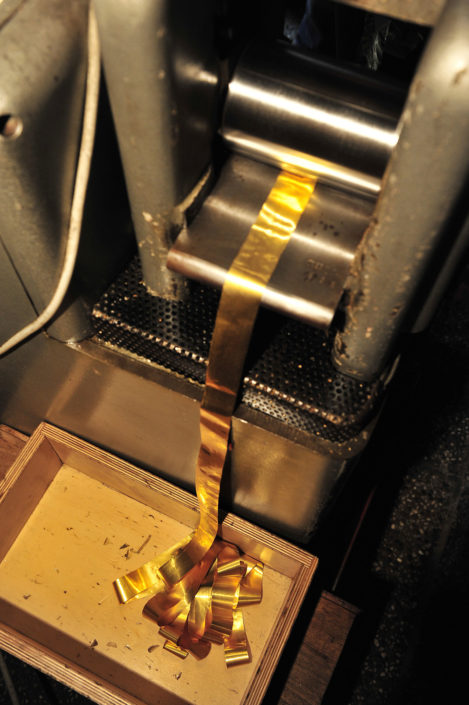

This transformation into a solid prepares the subsequent Laminating work, which thins it, changing it into a thin sheet from which the single raw material squares will be obtained, to be used in the Filling phase and then stacked on one another, separated by special paper sheets, and after that subjected to a first Hammering.

The semi-processed sheets thus obtained, cut into four parts and then stacked again, are afterwards subjected to a second manual Hammering carried out by master Marino Menegazzo who brings them to the final required thickness.

In the end comes the Cutting and Packaging phase during which skilled professionals handle the paper-thin leaves thus obtained with extreme precision in order to give them the required shape and finally place them in custom-made containers.